Asphalt Sealcoating Services in Green Bay, Wisconsin

Asphalt Seal & Repair – Providing Trusted Asphalt Services for Green Bay and Beyond

What Is Sealcoating?

Sealcoating effectively preserves the integrity of your paved surfaces, especially new asphalt. At Asphalt Seal & Repair, we use Gemseal’s sealing products that protect and enhance your parking lots, driveways, roadways, and more.

Our Sealmaster sealants provide a flat, slate-black color that gives asphalt a clean and renewed finish. Contact us today to learn more about our asphalt sealcoating services to boost your pavement’s appearance and safety.

How Frequently Is Pavement Sealcoating Required?

A properly applied asphalt sealcoat should last residential customers 4-5 years. Commercial properties should last 2-4 years. This is also dependent on the weather. The more severe the weather (more plowing, sanding, salting) the more wear will show earlier.

Contact us today to see if your paved surfaces could benefit from sealcoating.

Amount of Traffic

The amount of wear and tear on the sealcoat will affect its longevity; naturally, high traffic will cause the sealer to wear faster. For high-traffic areas, multiple coats of sealer are typically recommended, and you may need to schedule sealcoating services more frequently, around every 1-2 years.

Number of Coats Applied

Depending on certain factors, your asphalt may need more than one coat of sealer. Oftentimes, two coats of sealer are applied, with a third coat recommended for high-traffic areas. Each coat must fully dry and cure before the next one is applied.

Quality & Amount of Material Applied

The longevity of a sealcoat application is directly related to the quality of the pavement sealer used. If the sealer is low in solids or watered down, its durability will suffer.

The amount of sealer applied per coat is equally essential to the number of coats applied. To achieve successful results, the application must adhere to the manufacturer’s recommendations.

Contact us today to see if your paved surfaces could benefit from sealcoating.

Asphalt Seal & Repair Sealcoating Services

- We purchase directly from the manufacturer, which keeps your project’s timeline on track and within your budget.

- Newly sealcoated pavement is visually appealing and can increase the value of your property.

- Sealcoated pavement is resistant to gas and oil drippings, salt damage, and the harmful effects of chemicals.

- It prevents oxidation, sun and weather damage, and naturally melts snow and ice.

Reactive vs. Proactive Asphalt Maintenance

Reactive Maintenance

Reactive maintenance refers to maintenance services that are scheduled in response to a problem that has already occurred. Some of the disadvantages of this type of maintenance include:

- It’s a crisis-based approach.

- It causes unexpected downtime.

- It ultimately costs more.

Proactive Maintenance

Proactive maintenance is the preferred approach because it addresses minor problems before they worsen and prevents other issues from arising altogether. Some additional benefits include:

- It’s a preparation-based approach.

- It maximizes the pavement’s lifespan.

- It aids facility management metrics.

Our Sealcoating Process

We follow these simple five steps for each sealcoating service:

Prepare & Clean

We begin by cleaning the asphalt surface and edging areas that won’t be sealed.

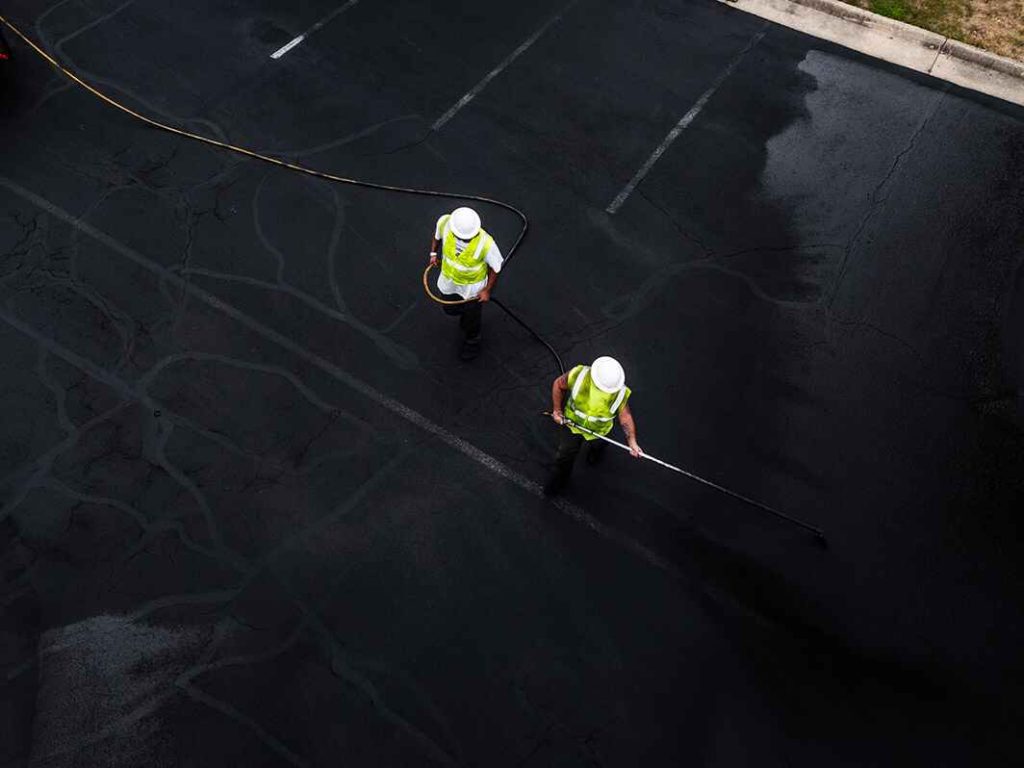

Apply Sealcoat

Depending on the size and type of pavement, a coal-tar or asphalt-based sealant is then sprayed, brushed or squeegeed evenly across the surface.

Dry & Cure

Once the first coat has cured, we apply a second coat to ensure a smooth, even finish.

Apply Pavement

Markings

Once both coats have cured, we apply new lane markings, parking spot lines, and other pavement striping as needed.

Key Benefits of Asphalt Sealcoating

Prevents Water Intrusion

Sealcoating fills surface cracks, down to even the tiniest hairline fractures, effectively blocking water from seeping in and causing damage beneath the surface. By preventing water intrusion, you significantly reduce the risk of potholes, base erosion, and structural breakdown, extending the life of your pavement.

Prevents Oxidation From the Sun

Over time, the sun’s ultraviolet (UV) rays cause the asphalt binder to oxidize and degrade, making the surface brittle and prone to cracking. Sealcoating acts as a protective barrier, slowing oxidation and preserving the asphalt’s strength and flexibility.

Protects Against Oils and Gasoline

Asphalt is petroleum-based, so when oil, gas, or any other petroleum-based liquid leaks onto asphalt, it acts as a binder that softens the pavement, making it more vulnerable to damage. Sealcoating protects asphalt from the damage caused by oil spots.

Extends Pavement Life

Routine sealcoating is a cost-effective way to extend the life of your pavement. When paired with proper maintenance, a well-constructed asphalt surface can last 15 years or more, saving you from costly repairs or full replacement down the line.

Increases Curb Appeal

Freshly sealcoated asphalt has a smooth, dark finish that looks clean and well-maintained. Whether it’s a parking lot or private drive, a polished surface gives your property a professional appearance and leaves a strong first impression on visitors or customers.

Factors That Affect the Longevity of the Sealcoat

Traffic Flow

High volumes of traffic, especially from heavy vehicles, can wear down the sealcoat over time. The more frequently a surface is used, the quicker the sealcoat will begin to show signs of wear, reducing its effectiveness and lifespan.

Weather Conditions

Extreme weather, especially in places like Wisconsin, can take a toll on your sealcoat. Freezing winters, humid summers, and fluctuating temperatures all contribute to the wear and tear on asphalt, causing the sealcoat to break down more quickly.

Proper Application

The durability of your sealcoat is only as good as the application process. Whether due to incorrect thickness or poor surface preparation, a poorly applied sealcoat will not provide the same protection and will wear away more quickly. Ensuring the job is done right is key to its long-term effectiveness.

Maintenance Routine

To keep your asphalt in top shape, regular maintenance is necessary. This includes clearing debris, sweeping the surface, and using the appropriate cleaning solutions to maintain a clean and smooth finish.

Seal & Stripe With Asphalt Seal & Repair

Sealcoating creates a clean and consistent look for your parking lot, offering an ideal surface for striping. We recommend sealing new asphalt lots within the first year and then every three to five years thereafter.

Parking lot striping is typically needed every 12 to 18 months. Because of these timelines, you can easily coordinate your sealcoating with your regular striping schedule. Combining these services also minimizes the disruption to your parking lot.

Sealcoating FAQs

Asphalt sealers, when applied correctly, are meant to preserve the oils present in asphalt and prevent oxidation. Oxidation is the primary cause of the drying, cracking, and potholing of asphalt.

It also helps to keep oil and gas from penetrating the asphalt. Sealcoat keeps the pavement looking black, fresh, and clean. In the winter, sealcoated asphalt will naturally melt snow and ice much faster than very gray oxidized asphalt.

This is very important…do not let anyone sealcoat your asphalt if the frost is still in the ground and the nighttime temperatures are still in the 40s! Never sealcoat if there is any snow or ice on the ground. The best time to seal is May through September.

We highly recommend 24 hours or longer for the best curing time. On days of high humidity or when sealing shaded areas, we highly recommend allowing the full 24 hours.

Remove all vehicles, no sprinklers for 24 hours, no lawn fertilization for 7 days

Our Service Areas

Wisconsin’s Premier Full-Service Pavement Maintenance Provider

After more than 5 decades in the industry, Asphalt Seal & Repair continues to be the premier pavement maintenance contractor of choice throughout Wisconsin.

Our Office

-

2077 Enterprise Drive

De Pere, WI 54115

(866) 460-2931

If you have a job outside of our service area, our Pave America partners can help.

Why Choose Sealcoating With Asphalt Seal & Repair?

At Asphalt Seal & Repair, we specialize in extending the life of your pavement with high-performance sealcoating solutions tailored to Wisconsin’s climate.

Our crew adheres to industry best practices for surface preparation, material selection, and application rates, ensuring long-term protection against oxidation, water intrusion, and chemical damage.

We source materials directly from trusted manufacturers, stay on schedule, and stand behind the quality of our work. Whether you’re managing a commercial property or maintaining a residential surface, we deliver consistent, high-value results with minimal disruption to your operations.

Request a quote today and discover why property managers, facility directors, and homeowners across Green Bay trust Asphalt Seal & Repair for reliable, professional sealcoating services.